In the market for a new offset press? You’ve come to the right place. You’re a seasoned print professional with decades of pressroom and production floor management under your belt.

Fill out the form below and receive a free offset press equipment evaluation. Plus, arrange for a no-fuss demonstration of a new RMGT sheetfed press. We’re just honest folks who are passionate about quality print.

Your submission has been sent!

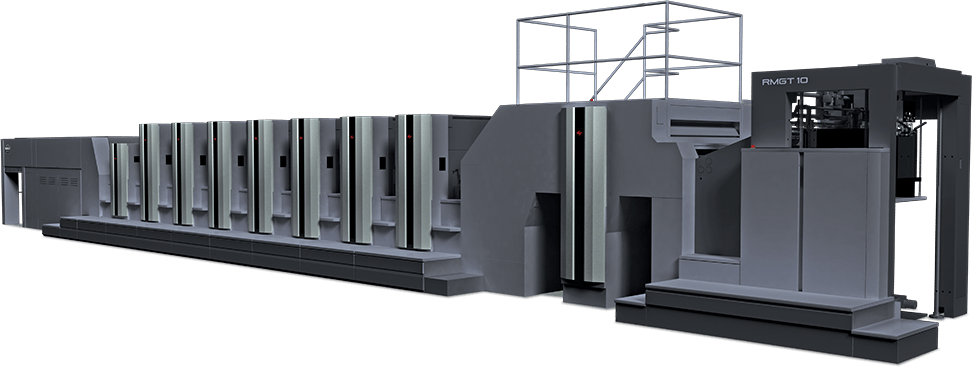

Fully automatic plate changers with simultaneous wash-up devices shave minutes off makeready. Dynamic feeders adjust to sheet thickness at the push of a button. In-machine storage of your job settings and print run parameters help you achieve repeatability and speed up your workflow.

Finding and holding onto skilled press operators continues to be a challenge. But what if your printing press could help eliminate the need for multiple veteran hands to keep your presses kicking out valuable revenue-generating work? You need an offset press that will increase productivity and address the staffing and labor challenges that printers know all too well.

Simulchanger Parallel – fully automatic, simulataneous plate-changing and blanket washing system

PQS-D (I+C+R) Print Quality Control System – quality inspection, printing density and automatic register adjustment functions

Overall Equipment Efficiency and real-time monitoring

Automatic nonstop feeder keeps your press running

Align yourself with an industry leader. Confidently purchase from a manufacturer and supplier that is committed to offset—equipment, parts and service.

RM Machinery was born out of providing and maintaining reliable Mitsubishi Lithographic Presses offset equipment to printers across North America

Mitsubishi and Ryobi establish joint venture company for sheetfed print technology, Ryobi-MHI Graphic Technology Ltd. (RMGT) in 2013

RM Machinery is the master distributor of the RMGT 10-Series in the USA

RM Machinery has multiple configurations of new RMGT sheetfed offset presses in stock and ready for installation

Acquire peace of mind with a new factory warranty coverage and minimize downtime with prompt in-person or remote response, no matter how infrequently you may need them.

New equipment factory warranty

Industry leading uptime and preventative maintenance program

Real-time remote equipment monitoring and predictive maintenance via AI and machine learning

Strategically located field technicians and press engineers in the United States and Canada

Affordable, in-stock spare parts and consumables inventory available from a single source

Your customers demand innovative solutions and a wide variety of products. That may mean pushing your existing equipment beyond its physical limits, testing your presses and press operators' ability to get the work completed.

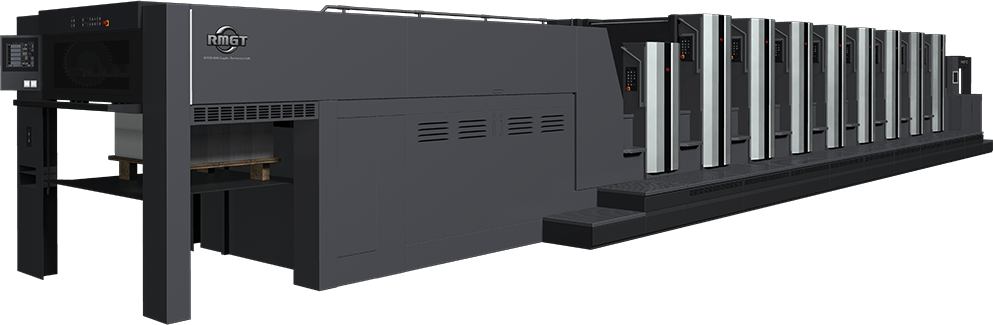

A press configured for versatility and expandability can help you complete more projects in-house and on the same machine. Many commercial printers have benefitted from the flexibility of equipping their operation with a machine that opened new markets such as packaging and label production. Maximize every square inch of your pressroom floor and explore revenue streams that may have seemed out of reach.

Configurations as wide-stock presses (LX – up to 1 mm) and Tandem Perfectors (TP)

RMGT 1060 LX ECO accommodates stocks up to 0.8 mm (32 pt) with skeleton transfer and is perfect for commercial and light packaging

RMGT 1060 LX Performance Package handles stocks up to 1 mm (40 pt) thick and has nonstop feeders for industrial packaging

RMGT 1060 TP LX delivers up to 0.8 mm (32 pt) with skeleton transfer to deliver industrial packaging performance industrial packaging performance

IR, conventional UV and LED UV capabilities on the same machine

Ability to configure a perfector with a single gripper to maximize live area coverage and reduce paper waste

Maximize your ROI and minimize the cost per impression. Leverage press automation technology to maxmize every job on every shift and reduce operator fatigue.

Count on an affordable in-stock spare parts and consumables program to reduce your downtime and help deliver industry-leading uptime.

Leverage a partnership-based relationship and avoid OEMs and dealers that treat you as a statistic.

Multiple press configurations in stock and ready for installation

Strategically located field technicians in the USA and Canada

Your single source for affordable, in-stock spare parts and consumables inventory

Industry leading uptime and preventative maintenance program

Banks are typically unable to offer financing on used equipment beyond 5 years. Once you’ve paid for your decades-old “new” press, it will probably be time to start looking for a replacement.

Stretch your capital investment to 96 months when you finance a fresh-from-the-factory, new offset press. You may be surprised to learn that many lenders do not even require a down payment.

You may be surprised to learn just how affordable the new RMGT 1060-Series Performance Package from RM Machinery can be for your print operation. Discover the productivity-enhancing and profit-boosting features of a new RMGT offset press.

Repeat customers purchasing multiple RMGT press configurations:

Kenosha, WI

RMGT 1050 LX-8

RMGT 1050 LX-6

RMGT 1050 LX-6

RMGT 1050 LX-6

Las Vegas, NV

RMGT 1050 LX-6

Omaha, NE

RMGT 1060 TP 7/1

RMGT 1050 LX-6

Newark, NJ

RMGT 1060 LX-6

RMGT 970ST-5-CC-SLD

City of Industry, CA

RMGT 1060 LX-8

Lithographix

Lithographix

Hawthorne, CA

RMGT 1060 LX-6

East Brunswick, NJ

RMGT 1020 LX-8-CC-DU-CC

© Copyright 2024 RM Machinery Inc.